METAL STRUCTURE MODULE FOR PHOTOVOLTAIC PANELS

Modules constructed from galvanized steel metal profiles with a minimum zinc coating of 275 g/m2

Used in the construction of photovoltaic parks with ground mounting

Photovoltaic panels per module: configurable for each individual project, arranged in two rows in portrait format

Modules per MW: configurable for each project, according to the number of panels/module and the power of the photovoltaic panels

Steel type metal structure profiles: S350GD, ZN 275 g/sqm

Complete installation kit: profiles drilled according to the plan and related assembly components

- Modules are assembled from cold-formed galvanized profiles with an anti-corrosion zinc layer, which does not require painting

- The metal structures for photovoltaic panels comply with the standards and requirements of EN 1993 – Eurocode 3: Design of steel structures

- The modules were designed by specialized engineers, resulting in a durable and efficient system both from the perspective of durability and cost-effectiveness

- The modules contain a complete installation kit: profiles drilled according to the plan and related assembly components

Topanel module categories for galvanized, ground-mounted photovoltaic structures

- Galvanized photovoltaic structure, ground-mounted, with columns made of galvanized profiles, fixed in the ground by driving with a sonic hammer

- Galvanized photovoltaic structure, ground-mounted, with ground screws

The assembly kit for the metal structure module for photovoltaic panels is made either according to the project provided by the beneficiary, or based on a project developed by a designer from the Topanel team.

For quote requests and design services, please contact us.

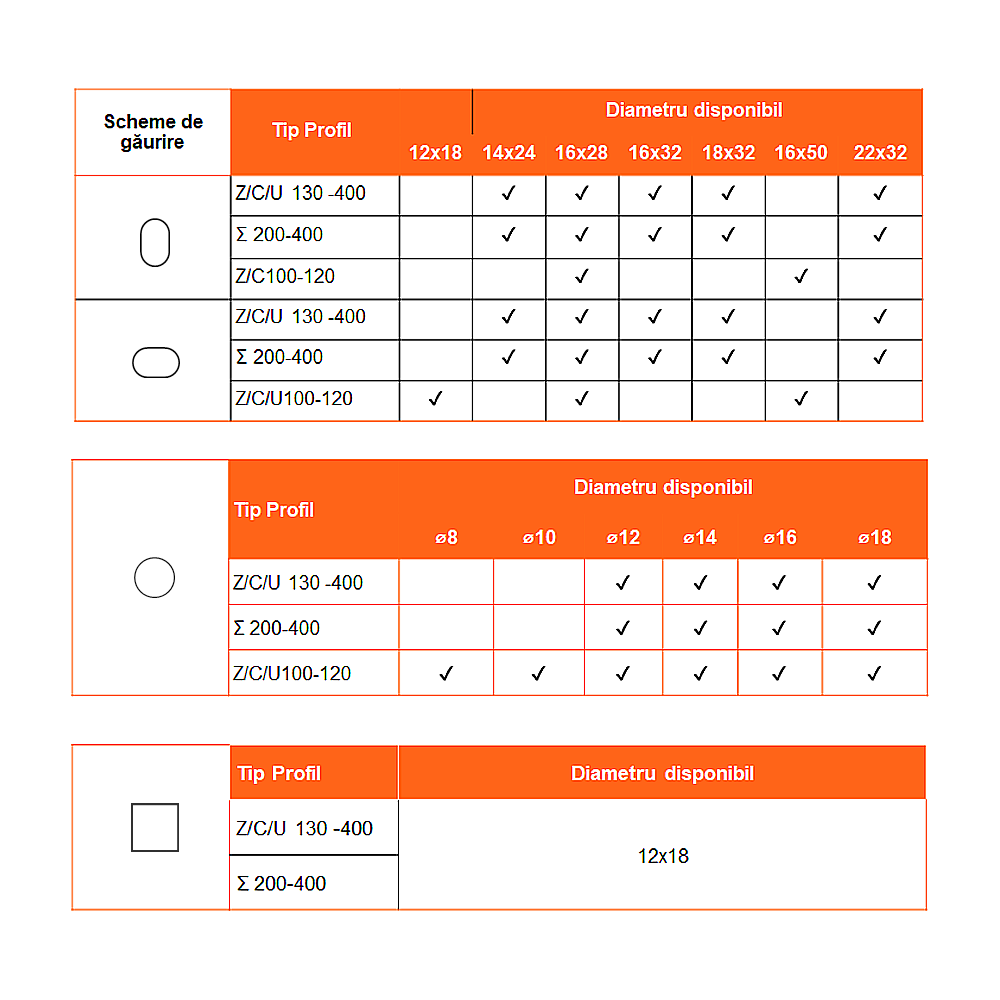

DRILLING SCHEMES

Galvanized profiles can be perforated according to the drilling plan made by the designer.

| WARRANTY The warranty period for TOP STEEL profiles depends on the usage environment and the degree of corrosion. This can cover the entire lifespan of the building. |

| PACKAGING Metal profiles are packaged in bundles with a maximum weight of 3 tons and are manually placed on horizontally arranged wooden battens. The number of wooden support battens is variable, determined by the length of the profiles. After placement, the profiles are secured with metal bands using specialized manual or pneumatic machines. |

| STORAGE The profiles are transported with a forklift to the storage or loading area. Short-term storage is done at a certain distance from the ground, on support battens placed on flat surfaces slightly inclined in the longitudinal direction of the profiles, so as to allow rainwater drainage. |

| TRANSPORT To ensure optimal transport conditions, the use of appropriate means of transport is recommended; galvanized profiles will be grouped in bundles that can be stacked and secured with straps to ensure the stability and security of the load. |

| UNLOADING The profiles are unloaded using mechanical devices: overhead cranes with textile slings, forklifts with protected forks (rubber). Unloading by tipping, throwing, or other methods that could damage the profiles or the zinc layer is strictly prohibited. |

DISCOVER THE TOPANEL PRODUCT RANGE

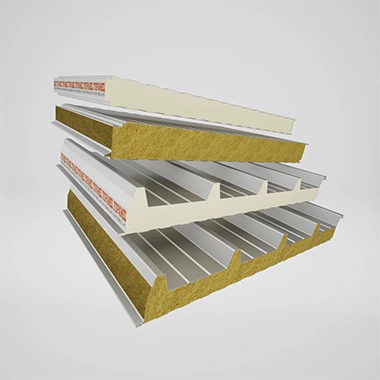

TOPANEL THERMAL INSULATION PANELS

PUR, PIR, and mineral wool thermal insulation wall and roof panels, fire-resistant, available from stock or by order

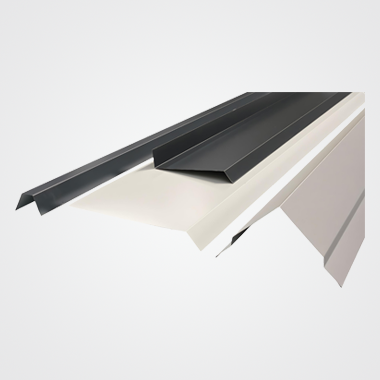

METAL AND RELATED ACCESSORIES

Hatches, skylights, sheet metal elements, sealing, or fixing elements for optimal thermal insulation

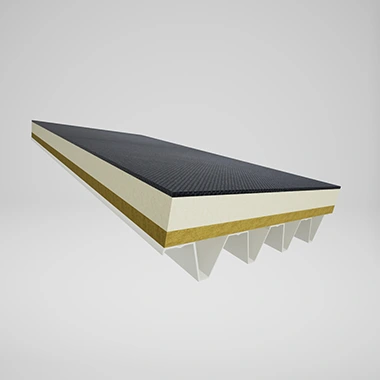

THERMOTOP ROOF SYSTEM

Technically approved roof system for industrial, civil, and agricultural buildings. It allows high load-bearing due to the low weight and compression resistance of PIR thermal insulation boards (170 kPa), while also having fire resistance according to current norms.

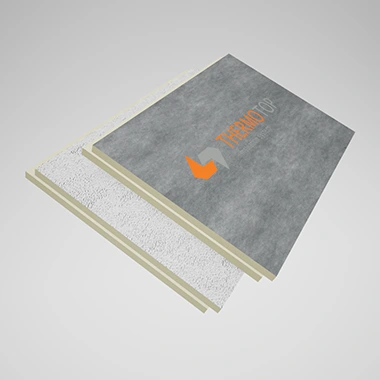

THERMOTOP PIR THERMAL INSULATION BOARDS

High-performance thermal insulation solution for residential, commercial, industrial, and livestock buildings. It provides an insulation degree almost double that of mineral wool and polystyrene, having a very low thermal conductivity coefficient (λ = 0.022 W/mK)

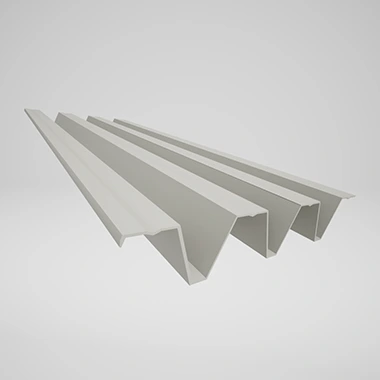

SELF-SUPPORTING CORRUGATED SHEET

Structural support for insulating, soundproofing, and/or waterproofing layers, used for walls and roofs. Available in H153 mm, H135 mm, H83 mm, and H53 mm versions

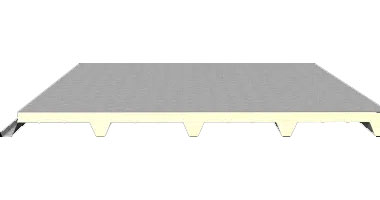

ASIGURĂ TERMOIZOLAREA MAXIMĂ CU PANOURILE PUR/PIR PENTRU ACOPERIȘURI

TOP ROOF CTB C5

- - pentru acoperișuri terasă (plane) -

- Grosimi: 30 - 150mm

- Nr cute: 5

- Față Ext/Int: Carton/bitumat Tablă zincată prevopsită în paletă RAL

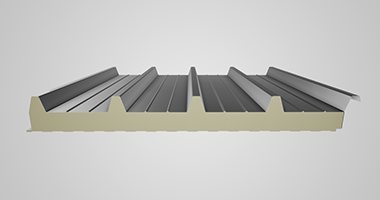

TOP ROOF C5

- - panou termoizolat acoperiș -

- Grosimi: 30 - 150mm

- Nr cute: 5

- Față Ext/Int: Tablă zincată prevopsită în paletă RAL

- Chertare la suprapunere: 80 - 250mm

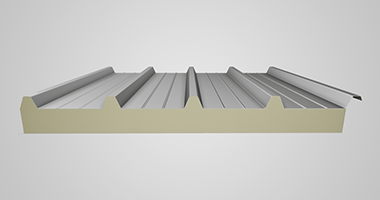

TOP ROOF ZOO C5

- - pentru aplicații zootehnice -

- Grosimi: 30 - 150mm

- Nr cute: 5

- Față Ext/Int: Tablă zincată prevopsită în paletă RAL / Rășină poliesterică armată cu fibră de sticlă

- Chertare la suprapunere: 80 - 250mm

TOP FRIGO DL

- - panou PUR/PIR camere cu temperatură controlată -

- Grosimi: 100-200mm

- Lungimi: 2 - 13.5m

- Fixare: Vizibilă - Dublu Labirint

- Față Ext/Int: Tablă zincată prevopsită în paletă RAL

- Finisaj: Lis/Clasic/Micro/Diamant

BENEFITS OF TOP STEEL GALVANIZED PROFILES

Reduced execution time and cost

The low weight of the galvanized profiles makes them much more maneuverable and faster to install

Precision in detail execution

Cold-formed galvanized profiles come cut to the size requested by the customer/installer and pre-drilled

Durability without maintenance costs

The quality of the steel (S350, Zn 275) from which the Topsteel profiles are made and the high degree of zinc coating provide a major plus in protection against rust or other deterioration over time

Very high diversity in applications

Cold-formed sheet metal profiles can be used in many construction solutions, due to heights between 100−400 mm, sheet thicknesses between 1.5−3 mm, and lengths

Reduction of costs on site

Because the galvanized profiles arrive at the site already pre-drilled, installation is easy, reducing execution times, thus optimizing site costs

RECENT ARTICLES

TOPANEL the first manufacturer of Thermal Insulation Panels in Romania with an Environmental Product Declaration In the construction industry, choosing the appropriate materials is essential for obtaining durable, energy-efficient structures with a reduced… READ MORE

TOPANEL the first manufacturer of Thermal Insulation Panels in Romania with an Environmental Product Declaration In the construction industry, choosing the appropriate materials is essential for obtaining durable, energy-efficient structures with a reduced… READ MORE Are thermal insulation panels efficient in optimizing energy costs generated by heating or cooling buildings? The construction industry has undergone impressive transformations throughout history, and currently this evolution continues at a sustained pace.… READ MORE

Are thermal insulation panels efficient in optimizing energy costs generated by heating or cooling buildings? The construction industry has undergone impressive transformations throughout history, and currently this evolution continues at a sustained pace.… READ MORE What is the price per square meter of thermal insulation panels? Guide for investment evaluation Regardless of whether you intend to build a modern industrial hall, construct an efficient warehouse, or arrange a… READ MORE

What is the price per square meter of thermal insulation panels? Guide for investment evaluation Regardless of whether you intend to build a modern industrial hall, construct an efficient warehouse, or arrange a… READ MORE TOPANEL Metal Structures for Ground-Mounted Photovoltaic Parks In a global effort to combat the impact of global warming, European and local authorities are investing significantly… READ MORE

TOPANEL Metal Structures for Ground-Mounted Photovoltaic Parks In a global effort to combat the impact of global warming, European and local authorities are investing significantly… READ MORE